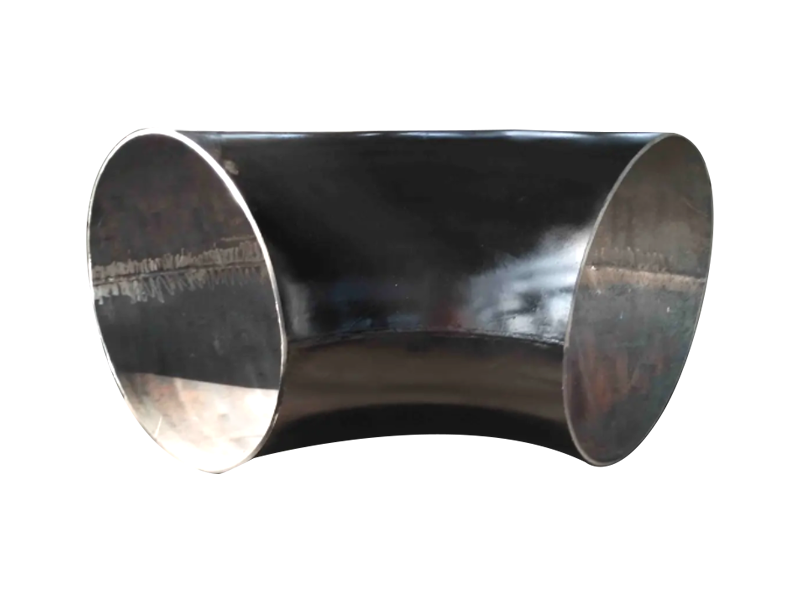

Recommended products for you

Our main product lines include three major categories: seamless, welded, and forged components; materials range from carbon steel and low-alloy steel to chrome-molybdenum heat-resistant steels and austenitic stainless steels. Product varieties encompass elbows, tees, reducers, pipe caps, large-radius bends, and manifold systems. Specifically, our seamless pipe fittings cover sizes from DN15 to DN800, while welded steel plate fittings are available in sizes from DN500 to DN3000. Forged components span DN6 to DN100, and manifold products range from DN80 to DN1200. Pressure ratings vary from SCH10 to SCH160 and XXS.

Industry Solutions

The product is widely used in industries such as power plants, construction projects, chemical pipelines, oilfield pipelines, and the petrochemical sector.

Petrochemical industry

The product is widely used in industries such as power plants, construction projects, chemical pipelines, oilfield pipelines, and the petrochemical sector.

Oilfield pipelines

The product is widely used in industries such as power plants, construction projects, chemical pipelines, oilfield pipelines, and the petrochemical sector.

Chemical pipelines

The product is widely used in industries such as power plants, construction projects, chemical pipelines, oilfield pipelines, and the petrochemical sector.

Construction project

The product is widely used in industries such as power plants, construction projects, chemical pipelines, oilfield pipelines, and the petrochemical sector.

Power plant industry

The product is widely used in industries such as power plants, construction projects, chemical pipelines, oilfield pipelines, and the petrochemical sector.

ORIENTAL PIPE FITTINGS

OUDI PIPELINE EQUIPMENT

OUDI PIPELINE EQUIPMENT

SINCE 1997

Yanshi Eastern Pipe Fittings Co., Ltd.

The company’s core business focuses on the R&D, manufacturing, and sales of steel pipe fittings. Its main product lines include three major categories: seamless, welded, and forged; materials offered span carbon steel, low-alloy steel, chromium-molybdenum heat-resistant steel, and austenitic stainless steel.

ABOUT US

Yanshi Dongfang Pipe Fittings Co., Ltd. was established in 1997 with a registered capital of 90 million yuan. Located in the Qujiazhai Industrial Zone, Gu County Town, Yanshi District, Luoyang City, the company occupies a site of 23,000㎡, with a total building area of 7,200㎡. The company is equipped with 67 sets of advanced machinery and equipment, including cutting, heating, forming, welding, heat treatment, precision machining, and surface treatment systems—such as a 3,000-ton hydraulic press, a DN800 push-bending unit, and a 400 kW heat treatment furnace. Additionally, it boasts 475 sets of specialized tooling, molds, and fixtures tailored for four major pipe fitting categories: elbows, tees, reducers, and pipe caps. Yanshi Dongfang also offers a comprehensive range of pipe fittings, featuring products from three key series: experimental analysis, forging, and high-pressure applications. These include the renowned Lihua fully automatic direct-reading emission analyzer and a 600KN universal testing machine. The company’s annual processing capacity reaches 6,000 tons, with a strong focus on ensuring top-notch quality and technical excellence, particularly in manufacturing high-pressure stainless steel elbows, hot-forged high-pressure tees, and manifold components designed for hydrogenation units.

Land area

Annual Processing Capacity

Complete set of equipment

Exported to Countries and Regions

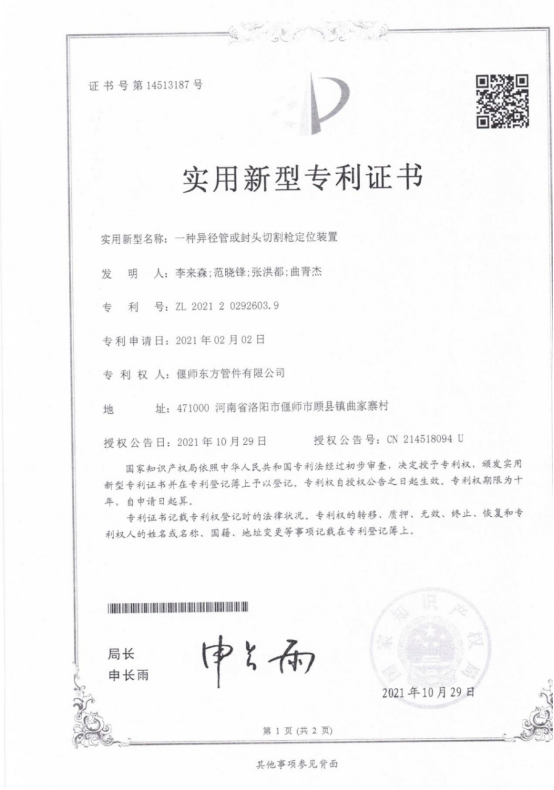

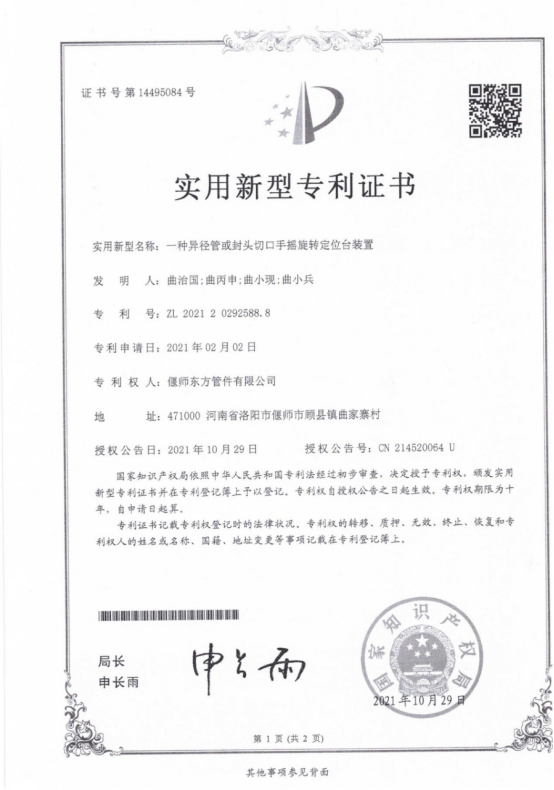

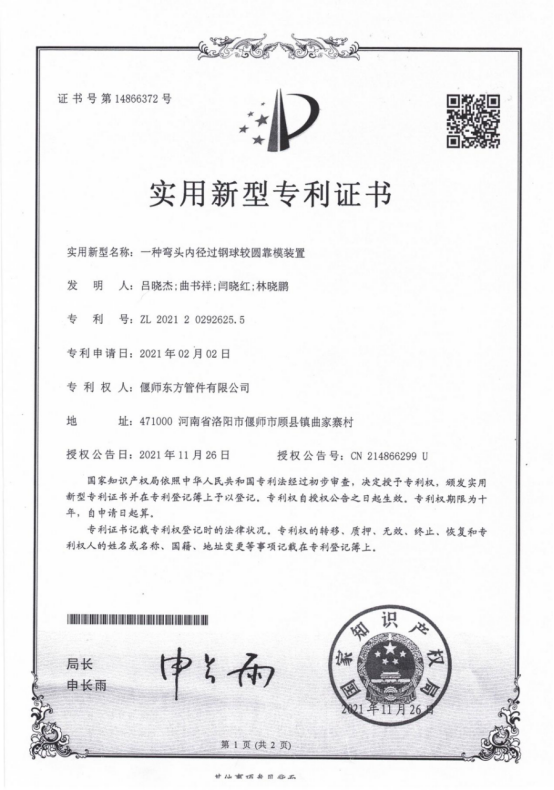

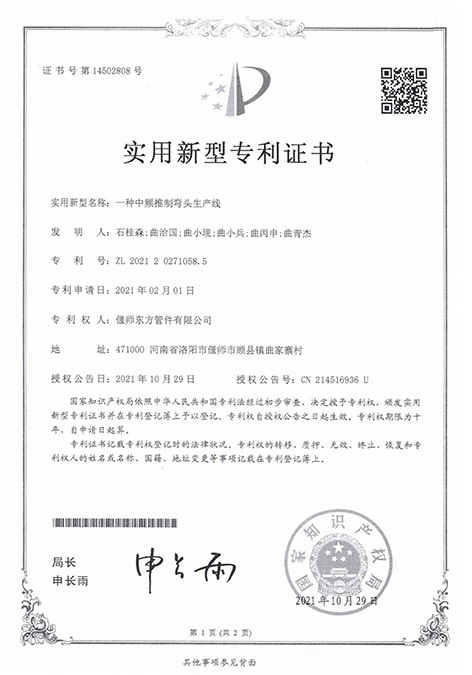

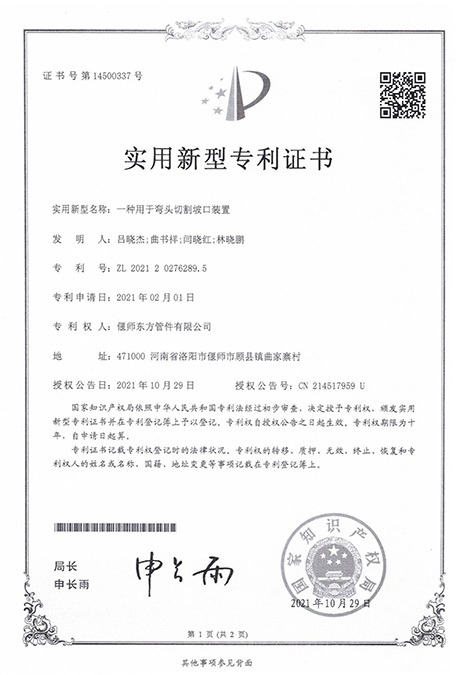

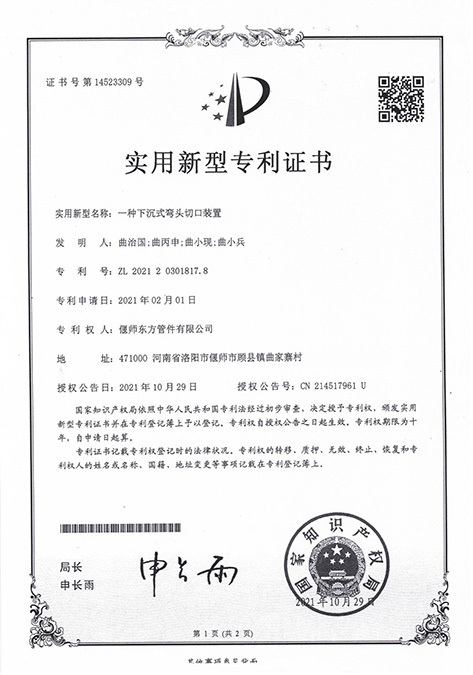

Scientific Innovation: Winning Through Quality

Our company is committed to achieving customer satisfaction, consistently delivering top-quality pipe fittings for refining and petrochemical facilities—and contributing to the nation’s energy security.

Innovation-driven, quality-focused, customer-first

The company’s corporate culture is rooted in technological innovation and a commitment to quality, continuously striving for cutting-edge technologies and advanced manufacturing processes. Through practical application, we constantly refine our product lineup. We warmly welcome valuable feedback and suggestions from our customers.

Design and Development

The company currently has 86 employees, including 10 with senior and mid-level technical qualifications, 15 junior technicians, 6 Level I and II inspection personnel, and 6 certified welders. All operational staff have been properly trained and are qualified to perform their duties, with mid- to senior-level operators accounting for 87% of the workforce. The company’s core business focuses on the research, development, manufacturing, and sales of steel pipe fittings.

Processing Capacity

The company is equipped with 67 sets of advanced machinery and equipment, including a 3,000-ton hydraulic press, a DN800 push-bending unit, and a 400 kW heat treatment furnace—covering cutting, heating, forming, welding, heat treatment, precision machining, and surface finishing processes. Additionally, it boasts 475 sets of molds, dies, and tooling fixtures for four major categories of pipe fittings: elbows, tees, reducers, and pipe caps. The facility also features three core product lines—Lihua experimental analysis systems, forging equipment, and pipe components—with over 10,000 specifications and models available. The company has an annual processing capacity of 6,000 tons.

Quality Management System

The company has successfully obtained certifications in quality, environmental management, occupational health and safety, as well as special equipment standards. It has established comprehensive environmental safety management and quality assurance systems that are continuously operational. Our company places a strong emphasis on site management, using process discipline as the key entry point. From re-inspection of raw materials upon arrival to rigorous process control and final product testing, we implement full-process quality tracking and product traceability.

Customize your exclusive fitting requirements

“

Contact the Eastern Pipe Fittings team today to discover how we can provide robust equipment support for your global business.

”

Blog

The company is committed to achieving customer satisfaction, consistently delivering top-quality pipe fittings for refining and petrochemical facilities, and contributing to the nation’s energy security.